In the intricate world of metal, a silent and persistent adversary lurks—corrosion. This natural process, often manifested as the rusting of metals, poses a formidable challenge to structures, machinery, and everyday objects. As we delve into the realms of understanding corrosion and its prevention, this guide aims to shed light on the nuances of this chemical reaction that affects the very essence of metals. Tailored for CBSE NCERT download, this exploration will equip students with insights into the science behind corrosion and the proactive measures essential for its prevention. Join us on this educational journey as we decipher the complexities of corrosion, unveiling the strategies that safeguard the longevity and integrity of metals in the face of this relentless foe.

Corrosion and its Prevention: A CBSE NCERT Downloadable Guide to Safeguarding Metals

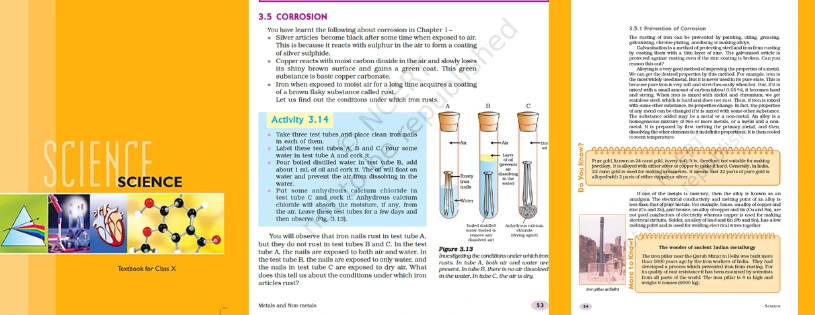

What is Corrosion?

Corrosion is the gradual destruction of materials, usually metals, by chemical reactions with their environment. The most common form of corrosion is rusting, which occurs when iron or steel reacts with oxygen and moisture in the air.

Causes of Corrosion

-

Moisture: Water is a primary contributor to corrosion. The presence of moisture accelerates the reaction between metal and oxygen.

-

Oxygen: Metals tend to corrode more rapidly in the presence of oxygen. This is why exposure to the open air often leads to corrosion.

-

Acids and Bases: Certain industrial environments, as well as pollutants in the air, can introduce acids and bases that accelerate corrosion.

Types of Corrosion

-

Uniform Corrosion: This occurs evenly across the surface of a metal, often giving it a pitted appearance.

-

Galvanic Corrosion: This happens when two different metals are in contact, creating a flow of electric current that speeds up the corrosion of one of the metals.

-

Crevice Corrosion: Occurs in confined spaces, such as gaps or crevices, where the metal is exposed to different concentrations of corrosive substances.

Prevention of Corrosion

-

Protective Coatings: Applying protective coatings like paint or corrosion-resistant materials can create a barrier between the metal and the environment.

-

Galvanization: Coating metal with a layer of zinc protects it from corrosion, as zinc corrodes more slowly than iron or steel.

-

Cathodic Protection: This method involves making the metal a cathode in a corrosion cell to prevent the oxidation process.

-

Proper Maintenance: Regular cleaning, lubrication, and inspection can help identify and address corrosion in its early stages.

Download Science notes

Factors Affecting Corrosion

1. Exposure of the metals to air containing gases like CO2, SO2, SO3, etc.

2. Exposure of metals to moisture, especially salt water (which increases the rate of corrosion).

3. Presence of impurities like salt (For example, NaCl).

4. Temperature: An increase in temperature increases corrosion.

5. Nature of the first layer of oxide formed: Some oxides like Al2O3 form an insoluble protecting layer that can prevent further corrosion. Others, like rust, easily crumble and expose the rest of the metal.

6. Presence of acid in the atmosphere: Acids can easily accelerate the process of corrosion.

Rate of Corrosion

The Deal–Grove model is often used to describe the formation of an oxide layer. This model helps in predicting and controlling oxide layer formation in a lot of diverse situations. Apart from this, the weight loss method is also used to measure corrosion. In this method, a clean, weighed piece of the metal or alloy is exposed to the corrosive environment for a certain duration. This is followed by a cleaning process that removes the corrosion products. The piece is then weighed to determine the loss of weight.

The rate of corrosion (R) is calculated as:

Where,

k = constant,

W = weight loss of the metal in time t,

A = surface area of the metal exposed,

ρ is the density of the metal (in g/cm³).

Corrosion Examples, Reactions, and Effects

Here are some typical examples of corrosion, as seen mostly in metals.

1. Copper Corrosion

When copper metal is exposed to the environment, it reacts with the oxygen in the atmosphere to form copper (I) oxide, which is red in colour.

2Cu(s) + ½ O2(g) → Cu2O(s)

Cu2O further gets oxidized to form CuO, which is black in colour.

Cu2O(s) + ½ O2(g) → 2CuO(s)

This CuO reacts with CO2, SO3, and H2O (present in the atmosphere to form Cu2(OH)2(s) (Malachite), which is blue in color, and Cu4SO4(OH)6(s) (Brochantite), which is green in color.

This is why we observe copper turning bluish-green in colour.

A typical example of this is the color of the Statue of Liberty, which has the copper coating on it turning blue-green in colour.

2. Silver Tarnishing

Silver reacts with sulfur and sulfur compounds in the air, giving silver sulfide (Ag2S), which is black in colour. Exposed silver forms Ag2S as it reacts with the H2S(g) in the atmosphere, which is present due to certain industrial processes.

2Ag(s) + H2S(g) → Ag2S(s) + H+2+(g)

CBSE Class 10th Downloadable Resources:

Being in CBSE class 10th and considering the board examinations you must be needing resources to excel in your examinations. At TestprepKart we take great pride in providing CBSE class 10th all study resources in downloadable form for you to keep you going.

Below is the list of all CBSE class 10th Downloads available on TestprepKart for both Indian and NRI students preparing for CBSE class 10th in UAE, Oman, Qatar, Kuwait & Bahrain.

SAMPLE PRACTICE QUESTION

Q:1 What is corrosion and why is it a concern for metals?

Ans: Corrosion is the gradual deterioration of metals due to chemical reactions with the environment. It's a concern as it compromises the structural integrity and longevity of metal objects.

Q:2 How does moisture contribute to corrosion?

Ans: Moisture accelerates corrosion by facilitating the reaction between metal and oxygen. Water acts as a catalyst in the formation of rust, a common form of corrosion.

Q:3 Can you explain galvanic corrosion and how it occurs?

Ans: Galvanic corrosion occurs when two different metals are in contact. It creates an electric current flow, accelerating the corrosion of one of the metals. This is why proper material selection is crucial in certain applications.

Q:4 What role do protective coatings play in preventing corrosion?

Ans: Protective coatings, such as paint or corrosion-resistant materials, act as barriers between the metal and the environment. They shield the metal from exposure to moisture, oxygen, and other corrosive elements.

Q:5 How does galvanization protect against corrosion?

Ans: Galvanization involves coating metal with a layer of zinc. As zinc corrodes more slowly than iron or steel, it sacrificially protects the underlying metal, serving as a shield against corrosion.

Download Question Bank

Post a Comment