Greetings, eager learners! Prepare to dive into the fascinating world of Basic Metallurgical Processes, where ores transform into precious metals. This educational journey is enriched by the invaluable resource at your fingertips — a CBSE NCERT Download. As Class 10 students, let's unlock the mysteries of metal production, guided by the comprehensive insights provided in CBSE NCERT. Are you ready to embark on a quest that combines ancient alchemy with modern knowledge? Let's delve into the captivating realm of Basic Metallurgical Processes!

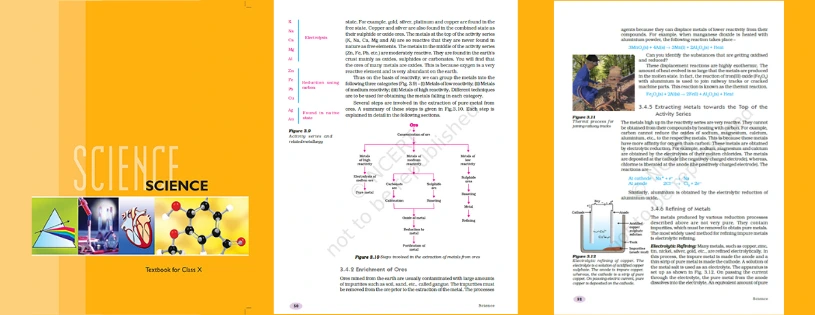

Mastering Basic Metallurgical Processes: A Guided Journey with CBSE NCERT Download

What Are Metallurgical Processes?

Metallurgical processes are the stepping stones that turn ores into the shining metals we encounter daily. From mining to refining, each step plays a crucial role in this alchemical transformation.

1. Mining Marvels: Extracting Ores from Earth's Embrace

Our journey commences with mining, where ores are unearthed from the depths of the Earth. We'll discover how different methods, from surface mining to underground excavations, extract these hidden treasures.

2. Crushing and Grinding: From Rocks to Precious Particles

Once extracted, ores undergo the mechanical dance of crushing and grinding. Learn how these processes reduce large chunks into finely powdered particles, setting the stage for the subsequent metallurgical ballet.

3. Concentration: The Art of Separating Ore from Gangue

Metals hide amidst impurities, and concentration is the art of separation. Dive into the methods employed to isolate valuable ore from the gangue, ensuring that the metal emerges in its purest form.

4. Smelting: Where Ore Meets Fire

Smelting is the fiery forge where transformation occurs. Witness how heat and chemistry conspire to extract metal from its ore, turning raw materials into molten metal ready for shaping.

5. Refining: Crafting Purity from Molten Gold

The journey isn't complete without refining, the meticulous process that purifies molten metal. Discover how impurities are cast away, leaving behind the gleaming essence of the metal we recognize.

Download Science notes

Principles of Metallurgy:

The metallurgical process can be classified as the following:

1. Crushing and grinding: The first process in metallurgy is the crushing of ores into a fine powder in a crusher or ball mill. This process is known as pulverization.

2. The concentration of ores: The process of removing impurities from ore is known as a concentration of minerals or ore dressing. In metallurgy, we concentrate the ores mainly by the following methods.

3. Hydrolytic method: In this method, we pour the ore over a sloping, vibrating corrugated table with grooves. A jet of water is allowed to flow over the surface. The denser ore particles settle in the grooves, and the impurities are washed away by water.

4. Magnetic separation: In this case, the crushed ore is placed on a conveyor belt. This belt rotates around two wheels in which one of the wheels is magnetic, and therefore the magnetic particles get attracted to the magnetic wheel and fall apart from the non-magnetic particles.

5. Froth floatation: In this process, we take the crushed ore in a large tank that contains oil and water. A current of compressed air is passed through it. The ore gets wet by oil and is separated from the impurities in the form of froth. Ore is lighter, and so it comes on the surface and impurities are left behind.

6. Roasting and calcination: In metallurgy, the process of heating a concentrated ore in the presence of oxygen is known as roasting. This process is applied in the case of sulfide ores. For ores containing carbonate or hydrated oxides, heating is done in the absence of air to melt the ores, and this process is known as calcination.

CBSE Class 10th Downloadable Resources:

Being in CBSE class 10th and considering the board examinations you must be needing resources to excel in your examinations. At TestprepKart we take great pride in providing CBSE class 10th all study resources in downloadable form for you to keep you going.

Below is the list of all CBSE class 10th Downloads available on TestprepKart for both Indian and NRI students preparing for CBSE class 10th in UAE, Oman, Qatar, Kuwait & Bahrain.

SAMPLE PRACTICE QUESTION

Q1: What are metallurgical processes?

Ans: Metallurgical processes are a series of steps involved in the extraction and refinement of metals from their ores.

Q2: How does mining contribute to metallurgy?

Ans: Mining is the initial step, where ores are extracted from the Earth. It provides the raw materials for metallurgical processes.

Q3: What is the purpose of crushing and grinding in metallurgy?

Ans: Crushing and grinding break down large chunks of ores into smaller particles, facilitating the extraction of metals in subsequent processes.

Q4: Why is concentration essential in metallurgy?

Ans: Concentration separates valuable ores from impurities (gangue), ensuring a higher percentage of the desired metal in the extracted material.

Q5: What role does smelting play in metallurgical processes?

Ans: Smelting involves heating ores to high temperatures to extract the metal. It transforms the concentrated ore into molten metal.

Download Question Bank

Post a Comment